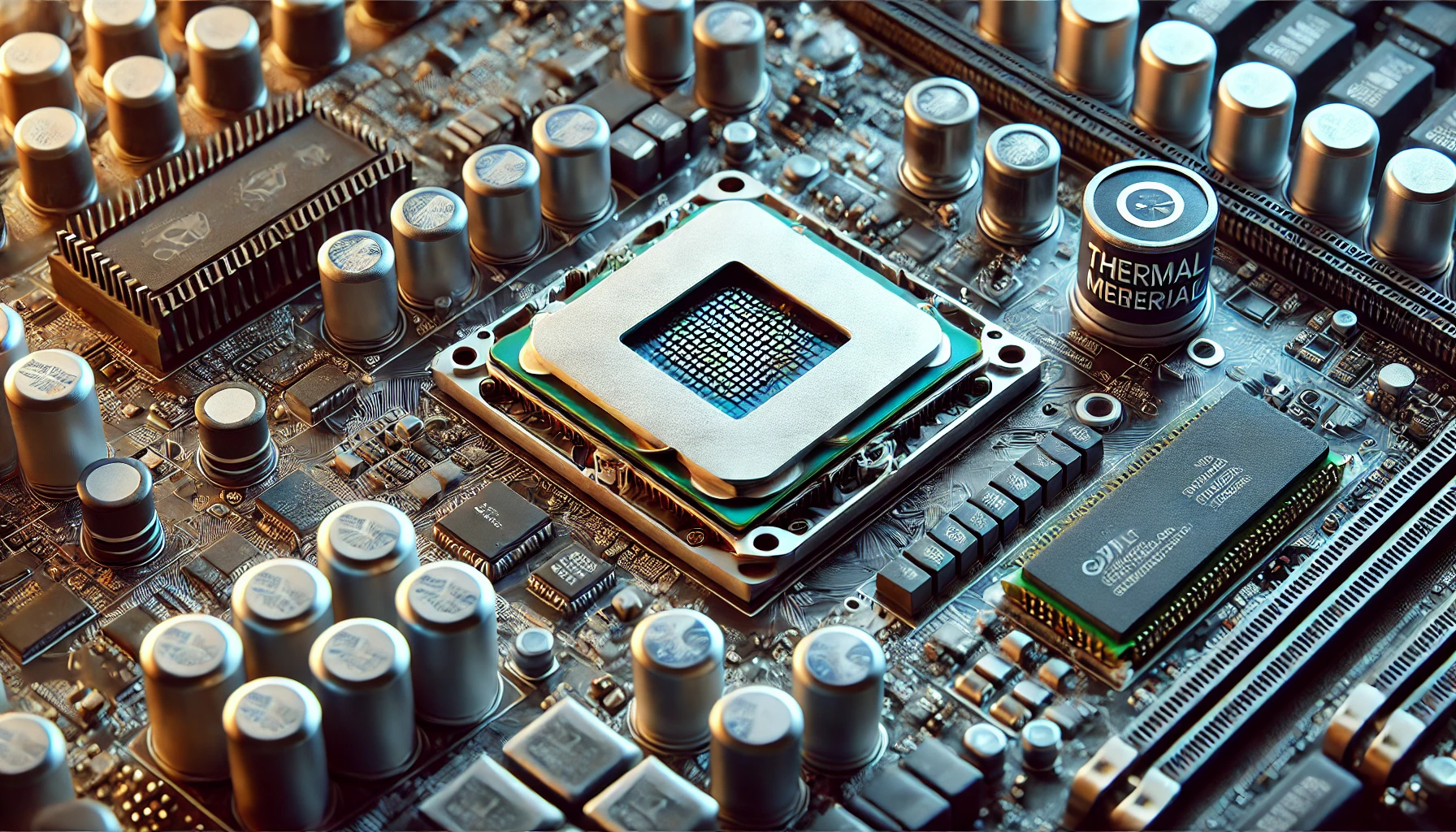

Product Line – Thermal Materials

PRODUCT DESCRIPTION

Product Line – Thermal Materials refers to a range of specialized materials designed for thermal management in electronics, automotive, industrial, and energy applications. These materials help dissipate, insulate, or direct heat to protect components and optimize system performance.

Product details

Thermal materials come in various types, each with specific characteristics tailored for different applications:

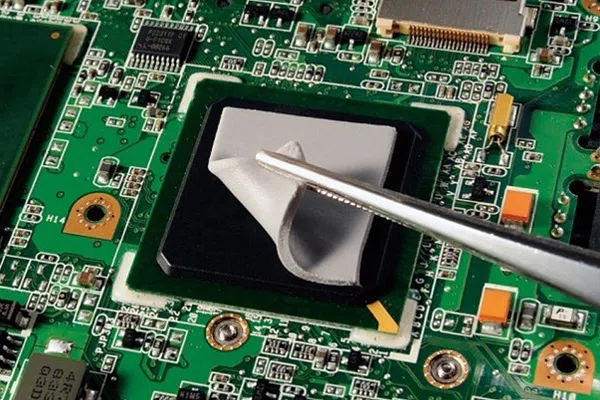

(A) Thermal Interface Materials (TIMs)

| Material Type | Thermal Conductivity (W/mK) | Application |

|---|---|---|

| Thermal Grease / Paste | 1 – 15 | CPU, GPU, telecom modules, high-power electronics |

| Thermal Pad | 1 – 10 | PCBs, LED modules, OLED displays |

| Thermally Conductive Adhesives | 1 – 8 | Bonding and heat transfer in electronic modules |

| Thermal Tape | 0.5 – 5 | LED applications, sensors, communication devices |

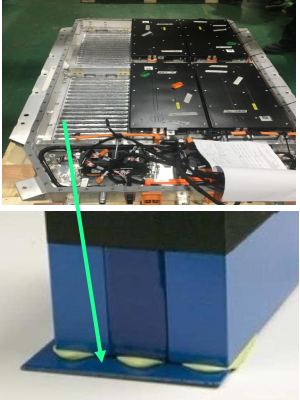

(B) Phase Change Materials (PCM)

- Thermal Conductivity: 2 – 10 W/mK

- Function: Absorbs and releases heat by changing phase (solid ⇌ liquid), used in EV batteries, thermal storage systems, electronics.

(C) Graphite Sheets

- Thermal Conductivity: 150 – 1500 W/mK (extremely high)

- Function: Fast heat dissipation in smartphones, laptops, servers.

(D) Heat Spreaders

- Material: Copper, aluminum, alloys

- Function: Distributes heat evenly to reduce thermal hotspots.

(E) Ceramic Thermal Insulators

- Low Thermal Conductivity (< 0.5 W/mK)

- Application: Insulation for inverters, high-temperature industrial systems.

Products

|

TF3221 | TF3235 | TPOT3210 | TG3236 | TA2200HA1 | TA2250 |

| Thermal Gap Filling | Thermal Potting | Thermal Gel | Thermal adhesive | |||

| Formulation | Silicone based | Epoxy based | ||||

| Usage temp. rang | -60-200’C | -60-200’C | -60-200’C | -60-200’C | -40-125’C | -40-125’C |

| Viscosity, cps | 35000-48000 | 150,000 | 4000 | 40g/min | 80000 | 30000(A)/6500( |

| Density, g/cc | 2.8 | 3.0 | 2.3 | 3.1 | 2.95 | 2.5 |

| Hardness(shore 00) | 50 | 35 | 50 | / | 85(shore D) | / |

| ermal conductivity, W/m.K | 2.1 | 3.5 | 1.0 | 3.6 | 3.0 | 1 |

| Cure condition | RT or heat cure | RT or heat cure | RT or heat cure | Pre-cure | Heat cure | RT or heat cure |

| Mix ratio | 1: 1 | 1: 1 | 1: 1 | One part | One part | 1: 1 |

| Flame rating | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 |

| ielectric Strength(kV/mm) | 10 | 10 | 10 | 10 | / | / |

| olume Resistivity (ohm-cm) | >1.0×10^12 | >1.0×10^12 | >1.0×10^12 | >1.0×10^12 | >1.0×10^12 | >1.0×10^14 |

| Self life, month@25C | 6 | 6 | 6 | 6 | 6(-20C) | 6 |

| Shear strength(Mpa) | / | / | / | / | 9 | 10 |

Advantage

✔ Efficient heat dissipation → Reduces component temperature, extending device lifespan.

✔ High thermal conductivity → Faster heat transfer compared to air or low-performance materials.

✔ Component protection → Prevents heat-related failures, improving durability.

✔ Versatile solutions → Available in liquid, sheet, and solid forms for flexible designs.

✔ Optimized system design → Reduces reliance on bulky cooling systems like fans or heat pipes.

Product Applications

🔹 Consumer Electronics: Laptops, smartphones, gaming consoles.

🔹 Automotive & EVs: Battery thermal management, ECU cooling, LED lighting.

🔹 Telecom & Servers: Routers, 5G base stations, data centers.

🔹 Medical Devices: Equipment requiring stable thermal control.

🔹 Renewable Energy: Solar panels, energy storage systems.