Cell – Cell to Cell Structural Bonding

PRODUCT DESCRIPTION

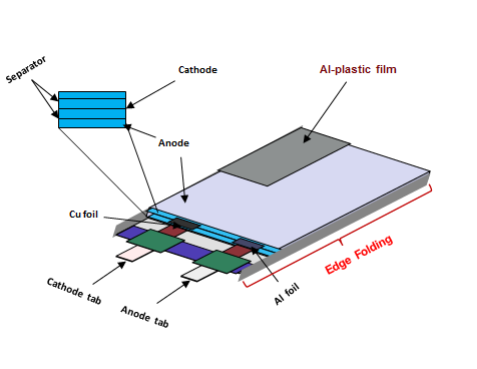

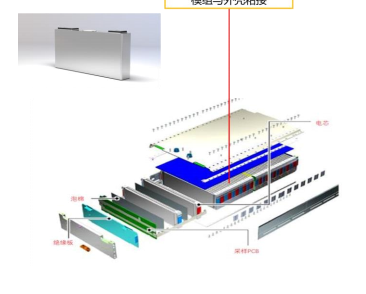

Cell – Cell to Cell Structural Bonding is a solution for bonding and securing battery cells together within a module or battery pack in lithium-ion battery systems, commonly used in:

🔹 Electric Vehicles (EV & HEV)

🔹 Battery Energy Storage Systems (BESS)

🔹 High-power electronic devices

This solution enhances mechanical durability, protects against vibrations and thermal shock, and improves thermal conductivity between cells, contributing to longer battery lifespan and improved safety of the battery system.

Product details

(A) Structural Adhesives

✔ Purpose: Strong bonding between cells to form a stable battery module.

✔ Materials Used:

- Epoxy-based Adhesives – High mechanical strength, heat-resistant.

- Polyurethane Adhesives (PU Adhesives) – Flexible, absorbs vibrations.

- Acrylic Adhesives – Quick bonding, good thermal stability.

(B) Thermal Conductive Adhesives

✔ Purpose: Provides both structural bonding and heat dissipation.

✔ Materials Used:

- Silicone-based Thermal Adhesives – High thermal conductivity, heat-resistant.

- Graphite-Infused Adhesives – Incorporates graphene for enhanced thermal performance.

(C) Foam & Spacer Materials

✔ Purpose: Ensures proper spacing between cells, absorbs mechanical shock and heat.

✔ Materials Used:

- Polymer Spacers – Thermal insulation between battery cells.

- Foam Pads – Absorbs vibrations and prevents mechanical damage.

▪ Good Insulation

▪ High Initial Strength and Final Bonding Strength ( >6 MPa)

▪ Suitable Viscosity for high efficiency dispensing

▪ Low Temp Curing (below 60C)

▪ Excellent Aging Performance (Thermal Shock,

85C/85%,etc)

▪ Good Elongation, Low Module, Excellent anti-vibration

Solution

▪ Pouch: HM PSA

▪ Prismatic: 2C PU

Prismatic– 2CPU

➢ Application:

Cell to Cell bonding in Module

Module bond to Pack

➢ Requirement:

• Good adhesion to Al & PET

• UL94-V0 Fire Resistant

• Good aging performance

• User friendly in dispensing and

cure process

• Low Module, Good Toughness, Antivibrtation

➢ Weldton Solution: 2C PU

Pouch– HMPSA

➢ Application:

Fixing between Pouch Cell

➢ Reuqirement :

• High initial strength;

• Auto dispensing ;

• User friendly;

• Stability under high temperature ;

➢ Weldtone Solution :

HMPSA HM9210

◼ Auto process, replace tape solution , saving manpower and

total production cost

◼ Consistent dispensing, stable under high temperature (4-8 hrs

continuous heating)

◼ Pressure sensitive, high initial strength

◼ Low Odor, Environment friendly

| Test Item | Unit | Weldbond 3507-0731 |

Weldbond 32297 |

| Appearance | NA | Light Yellow | White |

| Curing | NA | Moisture | Moisture |

| NCO含量 | % | 1.42 | 1.67 |

| Open Time | ≥5min | 5min | 6min |

| Viscosity | 170℃ | mpa·s | 7675 |

| T Peel | 30s Initial | N/8mm | 13.34 |

| 72h Final | N/8mm | 22.30 | 15.35 |

Advantage

✅ Enhances mechanical durability, preventing damage from impacts and vibrations.

✅ Improves thermal safety, helping to regulate temperature between cells.

✅ Prevents cell displacement, ensuring a stable module structure.

✅ Reduces fire and explosion risks, minimizing short circuits caused by impact or electrical failure.

Product Applications

🔹 Electric Vehicle Batteries (EV, HEV, PHEV) – Securely bonds pouch or cylindrical cells (18650, 21700) together.

🔹 Battery Energy Storage Systems (BESS) – Fixes battery cells in large-scale energy storage systems.

🔹 Drones & Aerospace Batteries – Ensures battery stability in high-vibration environments.