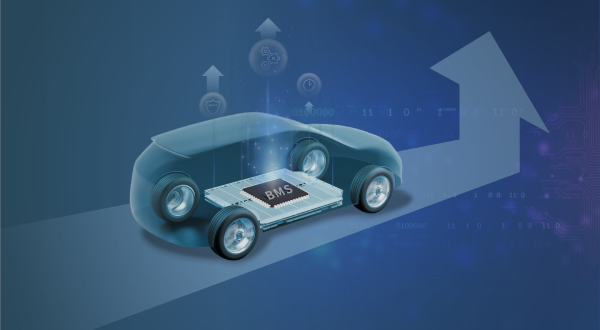

BMS- Thermal Conductive Potting

PRODUCT DESCRIPTION

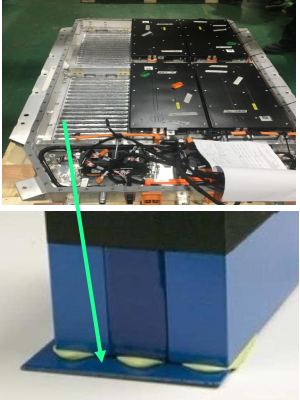

BMS (Battery Management System) – Thermal Conductive Potting is a solution that involves encapsulating electronic components in a thermally conductive potting compound to enhance heat dissipation and protection. This method plays a crucial role in maintaining the durability and efficiency of the BMS in demanding environments.

Product details

🔎 Key Functions of Thermal Conductive Potting

✅ Effective Heat Dissipation – High thermal conductivity potting compounds help transfer heat from electronic components to the environment, preventing overheating.

✅ Component Protection – Provides resistance against moisture, dust, and chemicals, prolonging the lifespan of BMS circuits.

✅ Vibration & Shock Absorption – Reduces mechanical stress, particularly in EVs and energy storage systems.

✅ Excellent Electrical Insulation – Prevents short circuits, ensuring the safety of the BMS system.

✅ Fire Resistance – Some potting compounds meet UL94-V0 standards, minimizing fire risks in case of thermal runaway.

🔹 Common Types of Thermal Conductive Potting Materials

🔸 Silicone Potting Compound – Excellent heat resistance, flexibility, and ideal for high-temperature environments.

🔸 Epoxy Potting Compound – High mechanical strength and chemical resistance but may be more brittle than silicone.

🔸 Polyurethane Potting Compound – Flexible, highly moisture-resistant, and well-suited for high-vibration conditions.

Product Line – Thermal Materials

| Products | TF3221 | TF3235 | TPOT3210 | TG3236 | TA2200HA1 | TA2250 |

| Thermal Gap Filling | Thermal Potting | Thermal Gel | Thermal adhesive | |||

| Formulation | Silicone based | Epoxy based | ||||

| Usage temp. rang | -60-200’C | -60-200’C | -60-200’C | -60-200’C | -40-125’C | -40-125’C |

| Viscosity, cps | 35000-48000 | 150,000 | 4000 | 40g/min | 80000 | 30000(A)/6500(B) |

| Density, g/cc | 2.8 | 3.0 | 2.3 | 3.1 | 2.95 | 2.5 |

| Hardness(shore 00) | 50 | 35 | 50 | / | 85(shore D) | / |

| Thermal conductivity, W/m.K | 2.1 | 3.5 | 1.0 | 3.6 | 3.0 | 1 |

| Cure condition | RT or heat cure | RT or heat cure | RT or heat cure | Pre-cure | Heat cure | RT or heat cure |

| Mix ratio | 1: 1 | 1: 1 | 1: 1 | One part | One part | 1: 1 |

| Flame rating | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 |

| Dielectric Strength(kV/mm) | 10 | 10 | 10 | 10 | / | / |

| Volume Resistivity (ohm-cm) | >1.0×10^12 | >1.0×10^12 | >1.0×10^12 | >1.0×10^12 | >1.0×10^12 | >1.0×10^14 |

| Self life, month@25C | 6 | 6 | 6 | 6 | 6(-20C) | 6 |

| Shear strength(Mpa) | / | / | / | / | 9 | 10 |

Advantage

Product Applications

🚗 Real-World Applications of BMS – Thermal Conductive Potting

✔ Battery Management Systems for Electric Vehicles (EV, HEV, PHEV) – Protects BMS circuits from excessive heat and mechanical shocks.

✔ Energy Storage Systems (BESS) – Ensures long-term operational stability in various environmental conditions.

✔ Industrial & Aerospace Electronics – Absorbs mechanical stress and protects components in extreme environments.

🔹 In summary, Thermal Conductive Potting is an essential solution for enhancing the durability, thermal management, and safety of BMS, ensuring reliable operation in modern lithium-ion battery systems. 🚀