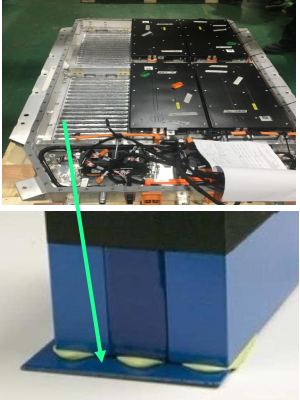

Battery Pack – Pack Sealing

PRODUCT DESCRIPTION

Battery Pack – Pack Sealing is the sealing solution for battery packs to protect battery cells and internal components from environmental factors such as moisture, dust, chemicals, and extreme temperatures. This is a crucial step in lithium-ion battery manufacturing, enhancing the durability and safety of battery systems.

Product details

Cured Foam Gasket

▪ Manual Operation / Easy handling

▪ Low Product Efficiency

▪ High Cost (Stock for different size)

FIPG – Adhesive

▪ Bonding & Sealing, Difficult for Rework

▪ Good Bonding Strength

▪ Need Curing Time

CIPG – Dispensable Foam

▪ + Automation Production

▪ + Flexible Design

▪ + Cost Down

▪ – Need investment on foaming machine

Key Requirement

▪ Auto Dispensing, High Efficiency

▪ UL 94 V0

▪ IP 68 Sealing

▪ Excellent Aging and Anti-Chemical

▪ Good Bonding Strength , high compress

ration for sealing

Solution

▪ FIPG – MS (Modified Silicone)

Common Sealing Materials :

🔹 Liquid Gasket – Flexible, easy to apply, and offers excellent waterproof and dustproof properties.

🔹 Foam Gasket – High elasticity, water-resistant, and effective in reducing vibrations.

🔹 Silicone Sealant – Heat-resistant, chemical-resistant, and excellent electrical insulation.

🔹 Polyurethane Sealant (PU Sealant) – Strong adhesion, providing robust protection in harsh environments.

Advantage

✅ Waterproof & Dustproof (High IP Rating) – Protects the battery from moisture, water, and dust, ensuring long-term stable operation.

✅ Leak Prevention & Component Protection – Prevents harmful substances from entering, maintaining battery performance.

✅ Fire Resistance & Insulation – Some sealing materials are UL94-V0 certified for fire resistance and provide excellent electrical insulation, reducing short-circuit risks.

✅ Vibration & Shock Absorption – Helps secure the battery pack housing, minimizing mechanical impact from the external environment.

Product Applications