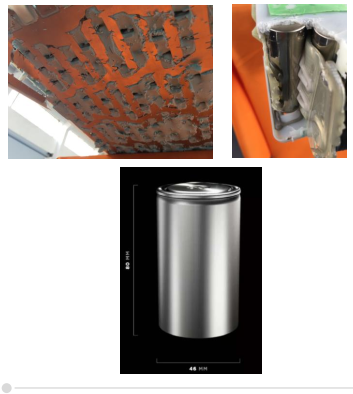

Module to Pack Foaming for Cylindrical

PRODUCT DESCRIPTION

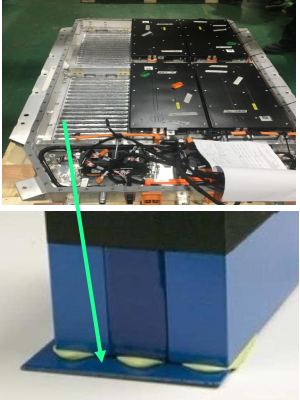

Module to Pack – Foaming for Cylindrical is a foaming solution used to fill the gaps between cylindrical cells in a module or battery pack. This process helps secure the cells, enhance heat dissipation, and ensure the safety of lithium-ion battery systems.

Product details

✅ Secures and protects battery cells – Holds battery cells firmly within the pack, preventing movement and vibrations.

✅ Enhances heat dissipation – Some foams contain thermally conductive materials that help distribute heat evenly among cells.

✅ Reduces battery system weight – Low-density foam is lighter than traditional bonding materials.

✅ Fire resistance for improved safety – The use of fire-retardant materials reduces the risk of thermal runaway and fire hazards.

Commonly Used Materials

🔹 PU Foam (Polyurethane Foam) – Lightweight, strong adhesion, excellent electrical insulation.

🔹 Silicone Foam – High-temperature resistance, vibration absorption.

🔹 Epoxy-Based Foaming Material – High mechanical strength, excellent fire resistance.

➢ Application :

Filling for Cylindrical Cell

➢ Requirement:

• Low density

• Fire resistance and insulation

• Process friendly

• Excellent aging performance

➢ Weldtone Solution:

PU Foaming Material

Advantage

✅ Strong fixation & improved mechanical durability

- Fills gaps between battery cells, preventing movement during vehicle operation or in high-vibration environments.

- Maintains the structural integrity of the module and pack, reducing damage from impact.

✅ Lightweight & optimized battery pack design

- Low-density foam reduces the overall weight of the battery system.

- Replaces traditional mechanical bonding methods such as adhesives or heavy brackets.

✅ Efficient heat dissipation & temperature control

- Some foams contain thermally conductive materials, helping distribute heat evenly across battery cells.

- Reduces the risk of overheating and improves thermal stability of the battery pack.

✅ Fire resistance for enhanced safety

- Many foam materials meet UL94-V0 fire resistance standards.

- Prevents fire spread in case of thermal runaway.

✅ Vibration reduction & increased battery durability

- Elastic foam helps absorb vibrations, protecting battery cells from mechanical stress.

- Crucial for electric vehicles, battery energy storage systems (BESS), and industrial equipment.

✅ Easy application & cost-efficient production

- Automated foaming process reduces labor costs and optimizes production.

- Expanding foam fills gaps without the need for manual cutting or adjustments.

✅ Environmental resistance & long-term durability

- Moisture-resistant, heat-resistant, and chemical-resistant properties.

- Ensures long-lasting performance of battery systems in various operating conditions.

Product Applications

🚗 Electric Vehicle (EV, HEV, PHEV) Batteries – Secures and protects cylindrical cells (18650, 21700, 4680).

⚡ Battery Energy Storage Systems (BESS) – Ensures stability of battery packs.

🛰 Aerospace & Industrial Equipment – Reduces thermal shocks and vibrations in harsh environments.