Module to Pack – Thermal Conductive Bonding

PRODUCT DESCRIPTION

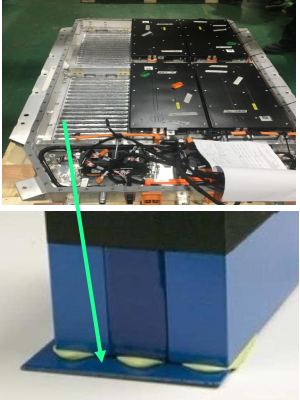

Module to Pack – Thermal Conductive Bonding is a solution that uses high thermal conductivity adhesives to bond battery modules to the pack casing. This ensures strong mechanical fixation, efficient heat dissipation, and improved safety in lithium-ion battery systems.

Product details

Key Functions of Thermal Conductive Bonding

✅ Strong Structural Bonding – Secures battery modules firmly within the pack.

✅ Efficient Heat Transfer – Enhances thermal dissipation from the module to the cooling system.

✅ Fire Resistance – Uses flame-retardant adhesives to improve battery safety.

✅ Vibration & Shock Absorption – Enhances durability by reducing mechanical stress.

Commonly Used Materials

🔹 2C PU Thermal Bonding Adhesive – High bonding strength with good thermal conductivity.

🔹 Epoxy-based Adhesives – Provides excellent thermal conductivity and mechanical strength.

🔹 Silicone-based Thermal Adhesives – Flexible, heat-resistant, and vibration-absorbing.

Application

▪ Cell/Module and Water-Cooling Thermal Bonding

Key Requirement

▪ AL & PET bonding strength ≥6 Mpa

▪ Thermal Conductivity≥1 w/mk

▪ Anti-Flammable –> V-0

▪ Good stability, anti-environment and dielectric

Solution

▪ 2C PU Thermal Bonding Adhesive

2C PU Thermal Conductive Bonding

| Property | 1.2W | 2.0W |

| Chemistry | 2C PU | 2C PU |

| Color | Grey | Grey |

| Viscosity (after mixture) |

180000 | 350000 |

| Density | 2.3g/cc | 2.6g/cc |

| Hardness | 50 | 55 |

| Mix Ratio | 1: 1 | 1: 1 |

| Tensile Shear Strength | Al to PET Film >8Mpa | Al to PET Film >6Mpa |

| Volume Resistance | ≥10^13 | ≥10^13 |

| Break Voltage | 15 KV/mm, 1mm thickness | 15 KV/mm, 1mm thickness |

| Dielectric Constant | < 4 (50Hz) | < 4 (50Hz) |

| Thermal Condustivity | 1.2 | 2.0 |

Advantage

✅ Secure Fixation, Enhanced Mechanical Strength

- Firmly holds battery modules inside the pack, preventing movement during vehicle operation or in high-vibration environments.

- Extends battery system lifespan by reducing mechanical stress.

✅ Efficient Heat Dissipation, Maintained Battery Performance

- High thermal conductivity adhesives facilitate heat transfer from battery modules to the cooling system.

- Minimizes overheating risks, extends battery life, and ensures stable performance.

✅ Flame Resistance, Improved Safety

- Many adhesives meet UL94-V0 flame resistance standards.

- Reduces the risk of fire or explosion caused by high temperatures or electrical short circuits.

✅ Vibration Reduction, Increased Battery Stability

- Elastic adhesives absorb vibrations and minimize physical impact on battery cells.

- Crucial for electric vehicles (EVs), battery energy storage systems (BESS), and industrial applications.

✅ Easy Application, Optimized Production Process

- Two-component PU adhesives (2C PU) or epoxy adhesives allow fast application and strong adhesion to aluminum (Al) & PET.

- Supports automated dispensing technology, reducing labor costs and increasing production efficiency.

✅ Resistant to Harsh Environments

- Excellent moisture resistance, heat resistance, and chemical durability.

- Ensures long-lasting battery performance under various environmental conditions.

Product Applications

🚗 Electric Vehicle Batteries (EV, HEV, PHEV) – Bonds battery modules securely to the pack casing while facilitating heat transfer.

⚡ Battery Energy Storage Systems (BESS) – Ensures stability and thermal management for long-term operation.

🛰 Aerospace & Industrial Batteries – Provides reliable bonding and heat dissipation in demanding environments.